Closed loop-capable stepper motors merge the benefits of stepper and servo motor technology. They run more smoothly and have a lower resonance than stepper motors, provide position feedback and control, feature short settling times, and exhibit no step loss at all. They are an alternative to stepper motors if energy efficiency, quiet running and a high load tolerance are required. Compared to servo motors, they have advantages due to their high torque at low speeds, short settling times, correct positioning without back swing and a lower price for sizes that are often smaller.

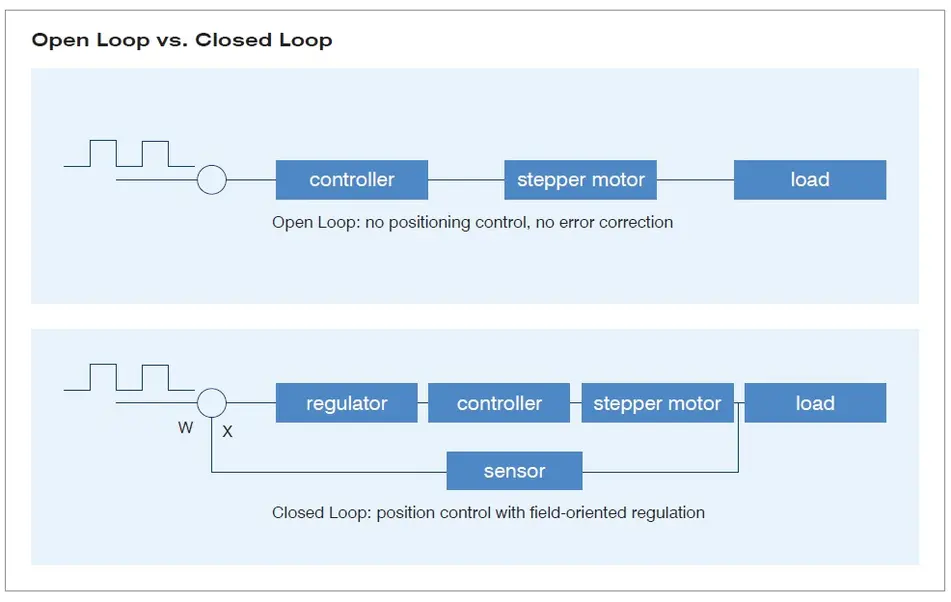

The closed-loop method is also referred to as sine commutation via an encoder with field oriented control. At the heart of closed-loop technology is the performance-adjusted current control as well as the feedback of the control signals. Using the encoder signals, the rotor orientation is recorded and sinusoidal phase currents are generated in the motor windings. Vector control of the magnetic field ensures that the magnetic field of the stator is always perpendicular to that of the rotor and that the field strength corresponds precisely to the desired torque. The current controlled in the windings provides a uniform motor force and results in an especially smooth-running motor that can be precisely regulated.

True/pseudo closed loop

There are stepper motors that dress themselves up as being closed loops and work with encoders but do not provide any field-oriented control with sine commutated current control. They only check the step position, and cannot correct step angle errors during operation. True closed loop with field-oriented control compensates step angle errors during a run and corrects load angle errors within a full step.

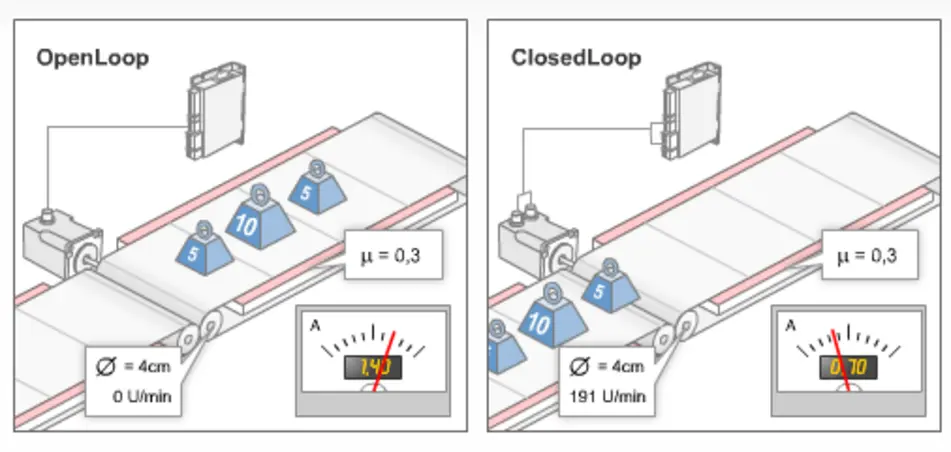

Classic stepper motors are reliable, economical drives that can be used for traveling to fixed positions. They operate in clock-direction mode, also called open-loop mode, which encompasses an open control loop in which control signals are not fed back. The lack of position feedback is thus a limitation because step offset or step loss due to overload, for example, cannot be detected. Furthermore, lower frequencies induce more resonance behavior, and a small load increase or a torque peak will cause the motor to lose steps, fall out of synchronization or even stop completely.

Closed-loop stepper motors are an advanced development of classical stepper motor technology. They eliminate the limitations and drawbacks of classical stepper motors:

- The calculation or purchase of a safety reserve (normally up to 50%) is not required

- Greater efficiency during load fluctuations and no stoppage on overload

- Energy-efficient operation due to intelligent current control

- Practically resonance-free

- Longer service life of bearings due to less heat and vibration

- Reduced acceleration times because high torque is achieved even at high rotational speeds

- Precise positioning due to monitoring and correction

Advantages over servo motors

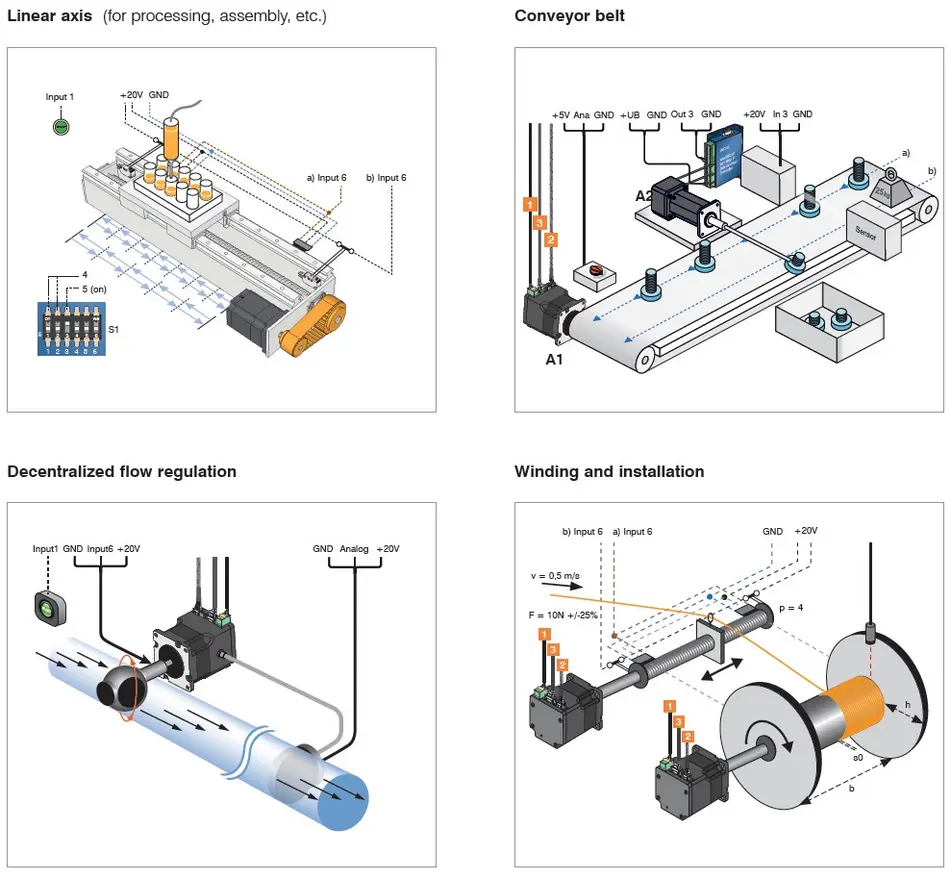

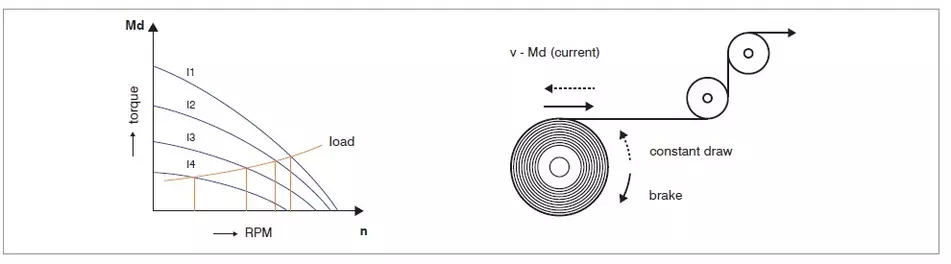

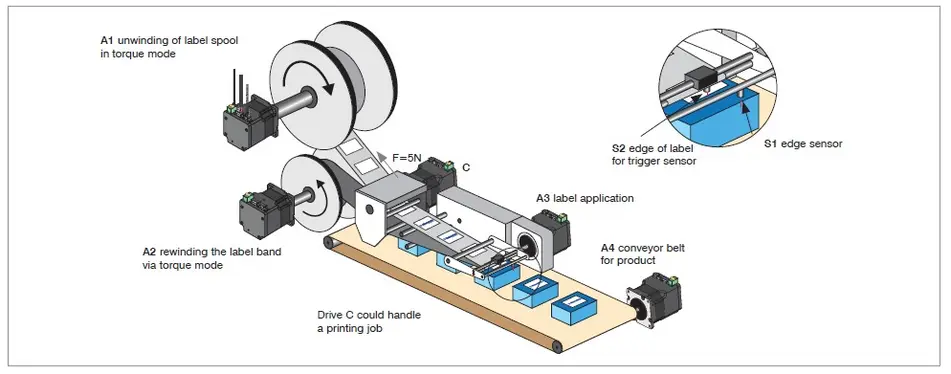

Closed-loop stepper motors from Nanotec are an alternative to servo drives in many cases, such as in winding applications or conveyor belt drives. Not only can the rotational speed and position be more precisely controlled, but the torque can be controlled as well (in torque mode, as typically required in winding applications). Closed-loop stepper motors combine the benefits of both worlds. They achieve the highest maximum torque, the best efficiency and optimum dynamics, but also feature the lowest torque ripple and exceptionally quiet running.

In torque mode, the closed-loop stepper motor functions analogously to a spring, whereby the spring tension characteristic curve can be set via a potentiometer. Thus, the motor delivers a stable force, even when the motor counteracts a force while at a standstill. When the force declines, the motor begins to turn proportionally to the declining force up to the set current and torque values. Thus, closed-loop stepper motors prove ideal for any type of winding, stretching and pressing applications.

Closed-loop-capable stepper motors are an alternative when the application requires:

- high torque at speeds up to 500 rpm and a compact, economical solution without a gearbox,

- fast commissioning without expensive tuning,

- a load to be held in position while at a standstill,

- avoidance of transient and free oscillation behavior (hunting), which is typical of servo motors and occurs especially on variable loads and pulsation, leading to intolerable following errors. On sudden load changes, servo motors miss their positions and must be corrected.

Ideal application areas for closed-loop stepper motors:

- Multiple-axis applications (serial, Ethernet, EtherCAT, CANopen)

- Positioning tasks with load changes

- Winding applications

- Belt drives (start/stop, positioning)

- Dosing pumps, filler systems

- Semiconductor mounting

- Wafer production

- Textile machines/industrial sewing machines

- Robotics

- Testing and inspection systems

- Applications that require smooth operation, short settling times and precise positioning