In the case of external linear actuators, the lead screw is permanently attached to the motor shaft and turns with the shaft when the motor is energized. If an external threaded nut – in standardized or anti-backlash version – is mounted on the lead screw and secured against rotating by an external guide, the threaded nut moves along the lead screw.

- Two motor lengths per NEMA size

- Various windings

- Different lead screw lengths and lead screw versions

- Can optionally be configured with encoder

- Can be combined with external threaded nuts (standardized or anti-backlash)

- Integrated connector

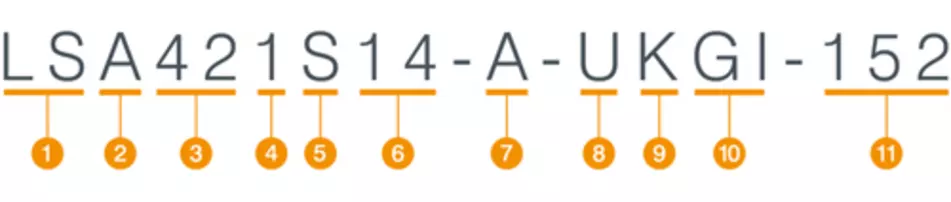

- External linear actuator

- Generation

- Flange size

- Phase angle: 1=1.8°, 0=0.9°

- Length: S, M, L, …

- Current: 14=1.4 A per winding

- B-shaft: A=no B-shaft, B=with B-shaft

- Thread type: U=ACME, T=trapezoidal

- Thread diameter: K=6.35 mm, see thread matrix

- Thread lead: GI=6.35 mm, see thread matrix

- Screw length: 102=102 mm, 152=152 mm

| Thread diameter |

mm |

inch |

| D |

3.5 |

0.138 |

| E |

3.5052 |

0.138 |

| G |

4.7625 |

0.1875 |

| H |

5 |

0.19685 |

| I |

5.55625 |

0.21875 |

| J |

6 |

0.23622 |

| K |

6.35 |

0.25 |

| Q |

9.525 |

0.375 |

| S |

10 |

0.393701 |

*Customized

| Thread lead |

mm |

inch |

| AI |

0.3048 |

0.012 |

| AP* |

0.6096 |

0.024 |

| AQ |

0.635 |

0.025 |

| AS |

0.79375 |

0.03125 |

| BA |

1 |

0.03937 |

| BF* |

1.2192 |

0.048 |

| BG* |

1.27 |

0.05 |

| BN |

1.5875 |

0.0625 |

| CA |

2 |

0.07874 |

| CB |

2 |

0.07874 |

| CD* |

2.116836 |

0.08334 |

| CL* |

2.4384 |

0.096 |

| CN* |

2.54 |

0.1 |

| DE* |

3.175 |

0.125 |

| EB* |

4 |

0.15748 |

| EG* |

4.2333 |

0.1667 |

| EV |

4.8768 |

0.192 |

| FC* |

5.08 |

0.2 |

| GA |

6 |

0.23622 |

| GI* |

6.35 |

0.25 |

| IA* |

8 |

0.314961 |

| JS |

9.7538 |

0.384 |

| KE* |

10.16 |

0.4 |

| MS* |

12.7 |

0.5 |